Explore four major trends in digital manufacturing—automation, digital twins, sustainability, and workforce digitization—and see how Autodesk solutions help factories implement and scale these innovations.

Since the first industrial revolution, factories have continued to evolve at a rapid pace.

In 2025, factories are increasingly defined by their digital tools and ability to perform data-driven decisions. Currently, there are four main digital manufacturing trends that impact production workflows, workforce engagement, and operational flexibility. Below, we explore these trends and the Autodesk solutions supporting them.

Trend 1: Intelligent automation is taking over routine operations

The next phase of automation is deeply integrated with artificial intelligence, turning production environments into adaptive, decision-making systems. Instead of static programming, today’s factories are embedding machine learning models into their operation. This allows robotic systems to continuously improve based on live sensor data. Such AI-enabled automation unlocks dynamic scheduling, flexible production cells, and even predictive intervention before failures occur.

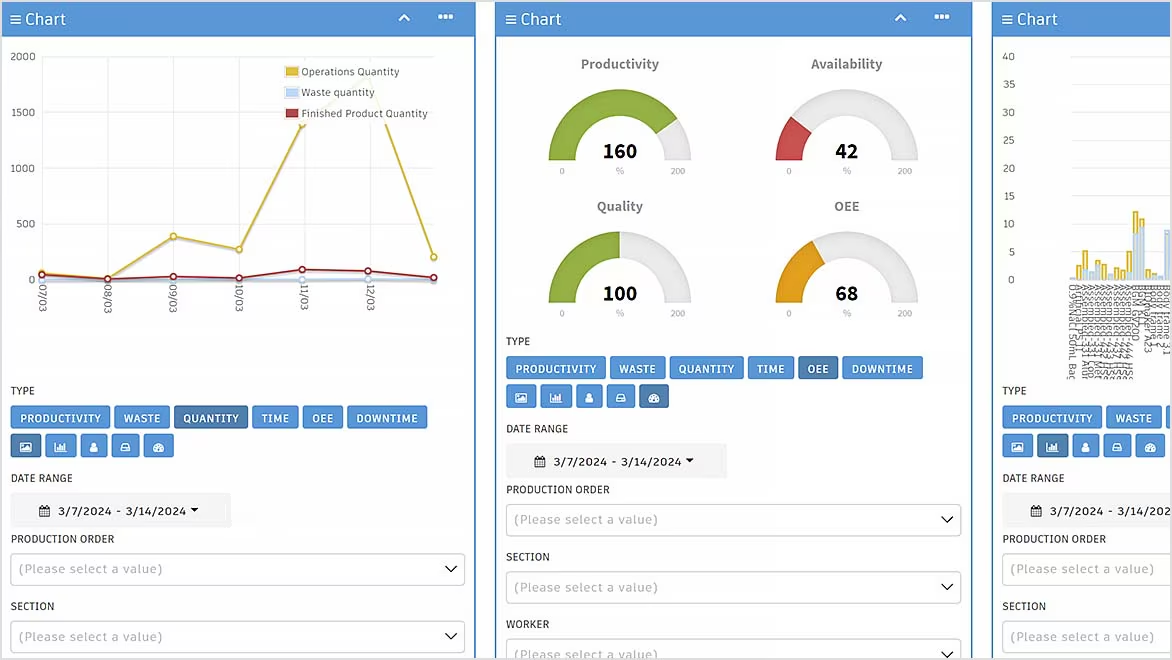

To support this shift, Autodesk Fusion Operations provides real-time production tracking and manufacturing execution system (MES) capabilities, enabling manufacturers to unify planning and production. Fusion Operations collects live data from machines, workstations, and operators and turns it into actionable insights. By providing a detailed digital thread of production data, Fusion Operations gives factory leaders the clarity to optimize workflows and maintain throughput as automation becomes more complex.

Trend 2: Digital twins for predictive and agile manufacturing

Digital twin technology has matured into a non-negotiable capability for manufacturers seeking agility. By creating virtual models of physical systems, companies are simulating production outcomes, testing design changes, and forecasting maintenance needs before implementing changes on the shop floor. To add, the fusion of digital twins with IoT sensors means these models update in near-real time, reflecting live operational conditions. This is a game-changer for both high-volume and high-variability environments that demand flexibility and reliability.

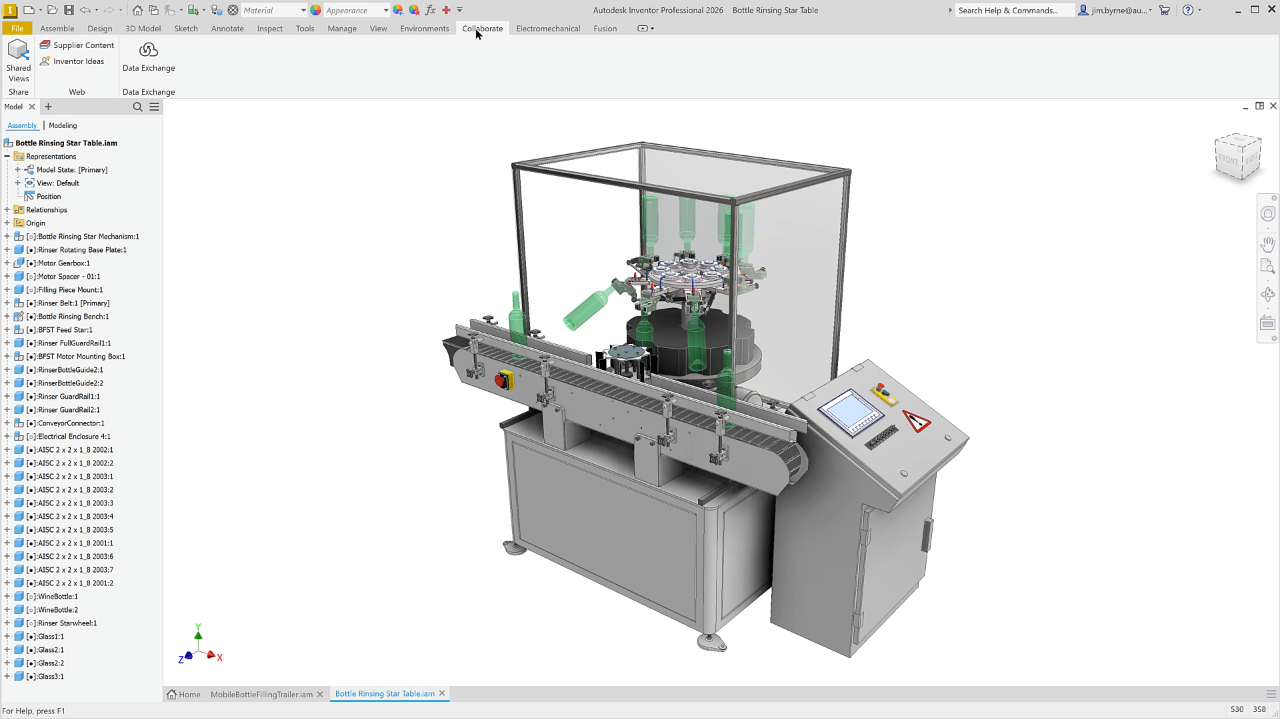

Autodesk Inventor helps operators create these accurate, simulation-ready digital models. Its advanced parametric design and mechanical simulation tools allow engineers to replicate geometry, motion, stress response, and dynamic behavior of assemblies. Inventor becomes part of the digital twin ecosystem when connected with downstream data tools or MES systems. This connection allows teams to virtually commission machines, test design iterations, and validate system-level interactions before physical deployment. For factories managing complex assemblies or bespoke production setups, Inventor accelerates the transition from static planning to digitally managed production.

Trend 3: Sustainability and energy efficiency in digital manufacturing

Manufacturers are facing growing pressure from governments and consumers to reduce environmental impact. Initiatives like low-emission operations, circular material use, and sustainable energy sources are becoming true business drivers. Factories are widely adopting strategies such as lightweighting, additive manufacturing, and material substitution to lower energy usage and carbon output. More importantly, sustainability is not only considered in operations, but in the design phase as well.

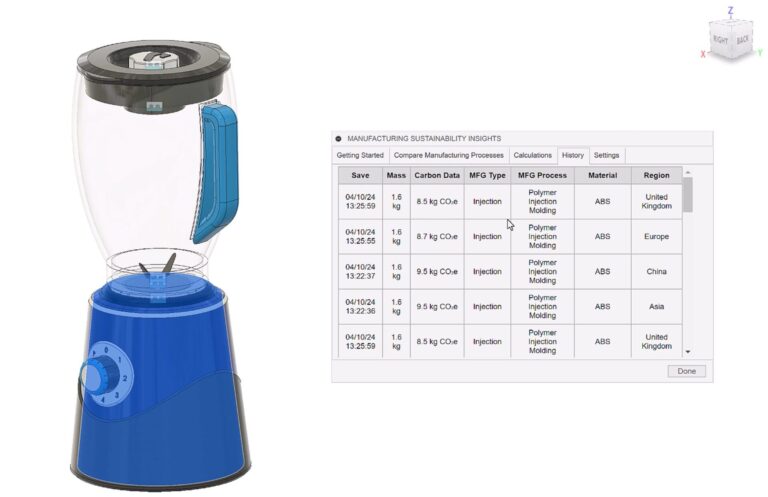

Autodesk Fusion plays a pivotal role in enabling sustainability in design by integrating comprehensive tools that allow designers to assess and mitigate the environmental impact of their creations. Through the Manufacturing Sustainability Insights (MSI) feature, Fusion provides real-time calculations of the carbon footprint associated with manufacturing processes, from cradle to gate. This includes evaluating the effects of material choices, manufacturing methods, and geographical considerations.

Fusion also has an extensive materials library so that designers can opt for eco-friendly options that reduce emissions and waste. By facilitating informed decisions on energy and material usage, Fusion helps designers create products that are not only innovative but also environmentally responsible, contributing to a more sustainable future in manufacturing.

Trend 4: Workforce digitization and training

With the rise of advanced technologies, skills development has grown from operating machinery to data interpretation, system monitoring, and cross-functional collaboration. Manufacturers need to invest in training platforms and digital documentation to onboard workers faster and empower them with intuitive, visual tools. As such, technologies like augmented reality, remote support systems, and standardized digital workflows are merging legacy knowledge and next-generation systems.

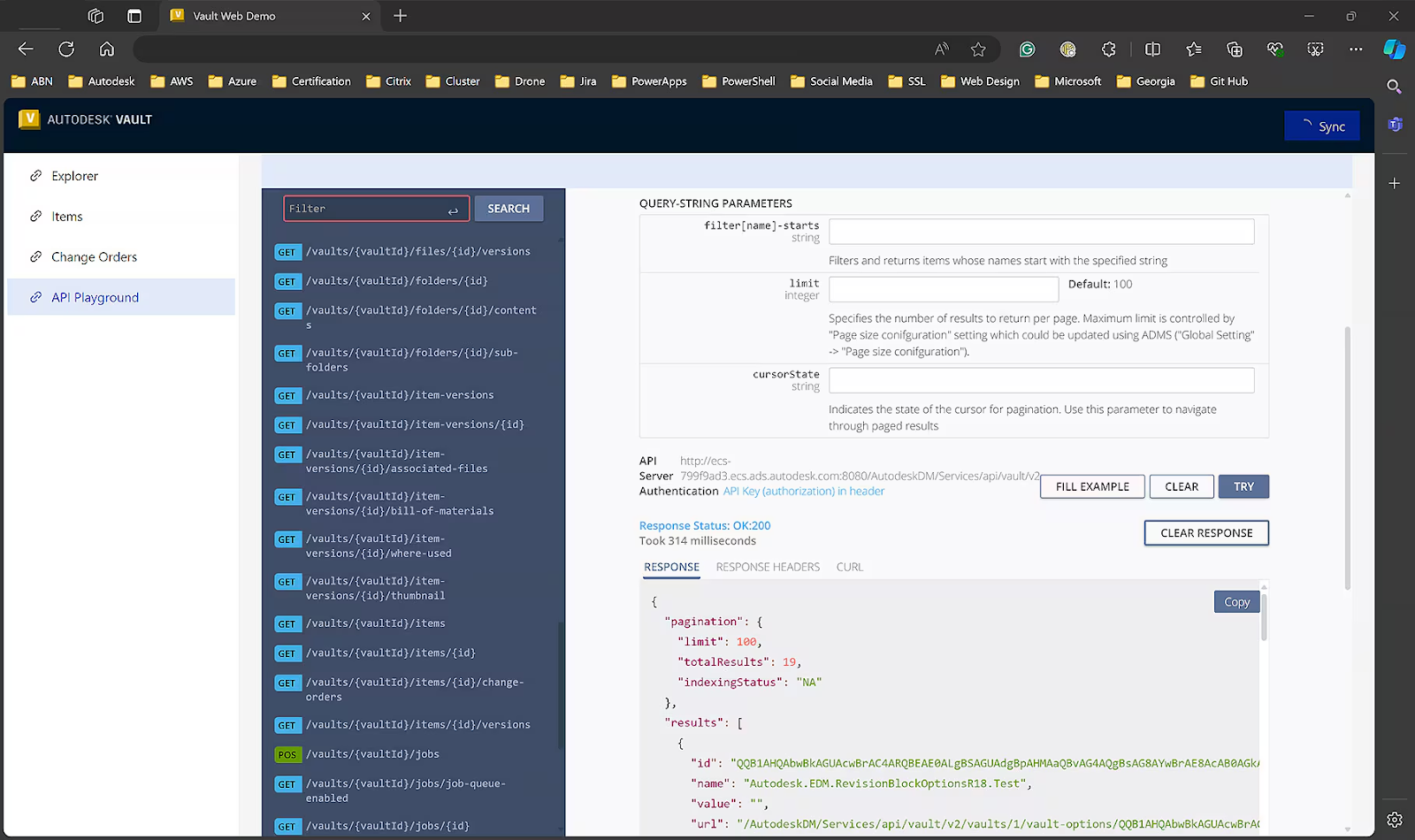

Autodesk Vault supports the digital manufacturing transition. It manages and centralizes all product and process documentation in a secure, searchable environment. As factories become more reliant on digital workflows, employees are always working with the latest approved files and revisions. For onboarding and continuous training, Vault can be seen as a centralized system. Here internal knowledge and formal documentation coexist, allowing manufacturers to scale knowledge without losing quality or compliance.

Supporting digital manufacturing with smarter tools

Digital manufacturing is already embedded in the way factories operate, evolve, and compete. With the right digital tools, manufacturers can transition from reactive to proactive operations and achieve a more integrated, holistic approach.